Electric Bus Air Conditioner for Electric Double Decker Bus

JLE Series, for 10-12m double decker bus, customized

The product consists of compressor, condenser, dry filter, expansion valve, evaporator, pipeline and electrical components.

The products are divided into several grades according to the different models and the size of the matched units. According to the structure, they are mainly divided into integral type and split type.

Technical Specification of Electric Double Decker Bus A/C JLE Series:

|

Model: |

JLE-IIIB-T |

|

|

Cooling Capacity |

Standard |

48 kW or 163776 Btu/h |

|

Heating Capacity |

Standard |

42 kW or 143304 Btu/h |

|

Expansion Valve |

EMERSON |

|

|

Air Flow Volume(Zero Pressure) |

Condenser (Fan Quantity) |

16000 m3/h (8) |

|

Evaporator (Blower Quantity) |

6000+6000 m3 /h (6+6) |

|

|

Fresh air |

1100 m3/h |

|

|

Unit |

Dimension |

750(L)×2000(W) ×1129(H) +800(L)×1800(W) ×377(H) |

|

Weight |

450 kg |

|

|

Cooling Power Consumption |

18kW |

|

|

PTC Power Consumption |

26kW |

|

|

Refrigerant |

Type |

R407C |

Technical Note:

1. The refrigerant is R407C.

2. The air-conditioning unit is overall installed above the rear engine, and should be considered for installation to be shoveled in as a whole, and shoveled out for overhaul. The air duct of the transitional connection between the unit and the air duct in the car should be easily installed.

3. It must be ensured that the condensing fan air enters and exhausts wind smoothly, and that the intake and exhaust air is effectively cut off without wind and short circuit. The wind speed of the vehicle side must be ≤5m/s.

4. The air duct of the transitional connection from the air conditioning unit to the air duct in the bus has a special shape, so the design should fully consider the operability of the installation and reduce the resistance of the air duct. The wind speed of the transition duct must be ≤12m/s.

5. The wind speed of the main air supply duct in the bus must be ≤8m/s.

6. It is best to set the air return grille separately according to the air volume ratio of the upper and lower floors. Or it can be set separately for the upper floor, and the lower floor returns air through the stairway.

6. Electrical control assemblies such as electric control boxes and inverters occupy a certain amount of space in the vehicle, and must be considered in a ventilated and waterproof position.

7. JLE-IIIB-T back-mounted (heat pump plus PTC) integrated battery thermal management function.

8. Please contact us at sales@shsongz.cn for more options and details.

Detailed Technical Introduction of the SZB Series Bus Air Conditioner

1. The overall frame structure, combined with the aluminum alloy shell, is large in size and light in weight.

2. Adaptive frequency conversion technology realizes synchronous variable speed conditions of compressors and fans, reducing operating energy consumption.

3. Custom development, modular design, light weight.

4. DC brushless fan, long life and light weight.

5.The heat pump design, compared with conventional transformation, can realize heat pump heating and reduce energy consumption.

6.CAN bus control, reserve interface and background for the subsequent popularization of bus networking technology.

7. Rich optional technology

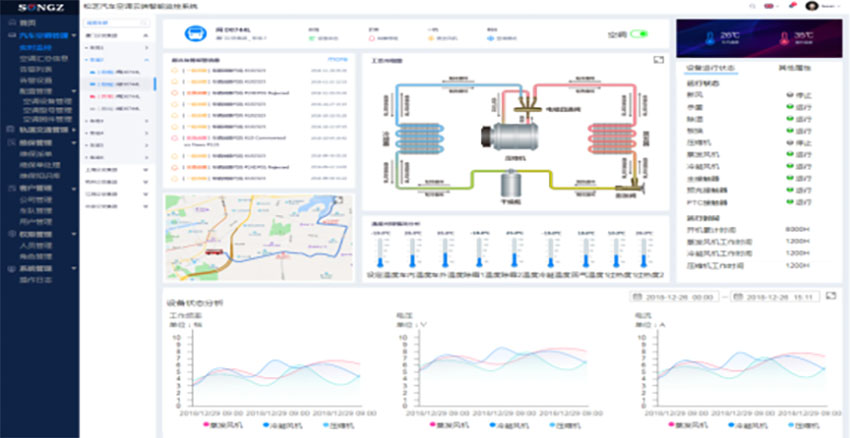

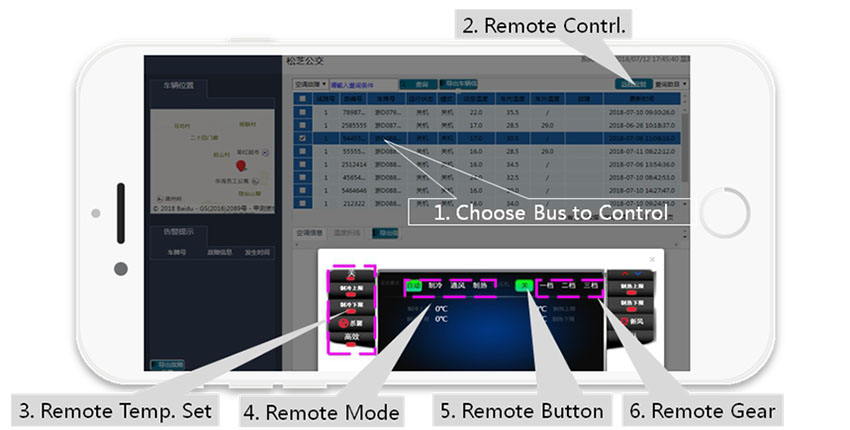

7.1. "Cloud control" function, realize remote control and diagnosis, and improve product service and monitoring capabilities through big data application.

7.2. High-voltage connection anti-loose technology

7.3. Integrated battery thermal management function, according to customer requirements without affecting the cooling effect of the vehicle.

7.4. DC750V high voltage

-

Air Purification and Disinfection System

-

Battery Thermal Management System for Electric ...

-

Electric Air Conditioner for Electric Bus and C...

-

Electric Air Conditioner for Electric Minibus a...

-

Electric Air Conditioner for Electric Bus and C...