SONGZ ultra-low temperature heat pump 5.0

Constant temperature and energy saving, let you warm in the extreme cold for the winter

The realization of efficient heating of new energy buses in winter has always been a pain point in the industry. The R&D team of SONGZ shares continuously explores the research and development of ultra-low temperature heat pumps, and strives to completely solve the problems of energy saving, comfortable, safe and reliable operation of low temperature heating.

In 2018, SONGZ ultra-low temperature heat pump 3.0 units were launched in batches, and they have been running so far, and the feedback is good; even if the snow is covered, the heat pump will operate as usual after defrosting!

In 2020, the SONGZ ultra-low temperature heat pump 4.0-quasi-two-stage compressor unit will be launched in batches, and the heat pump will still operate strongly when the ambient temperature is below -20℃!

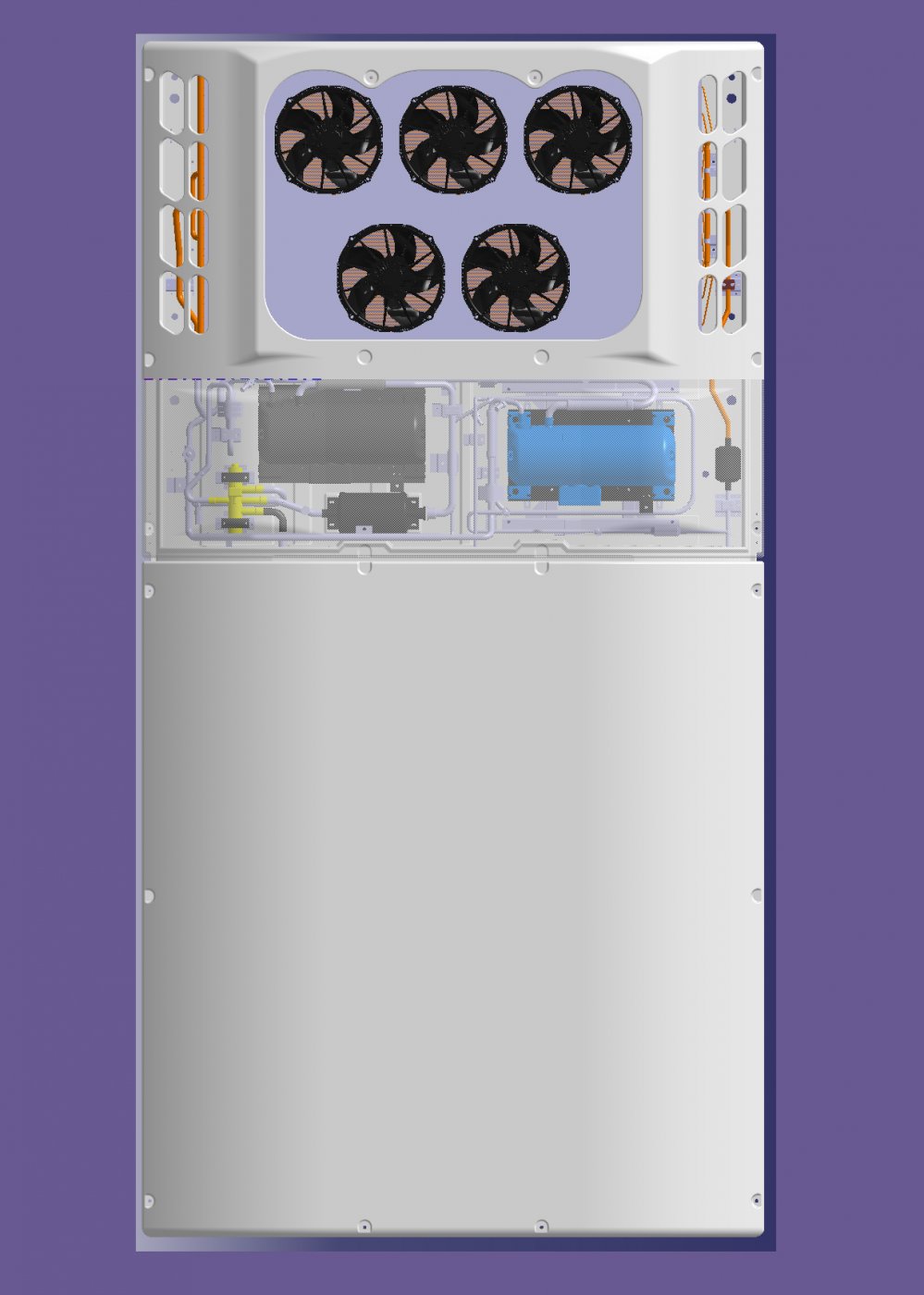

In January 2021, the SONGZ ultra-low temperature heat pump 5.0-two-stage compressor unit successfully passed the test, and all indicators met the design requirements. Compared with the ultra-low temperature heat pump 4.0 (quasi-two-stage compression) currently in batch operation, the heating capacity increased by 33% and the energy efficiency increased by 26 %. Two-stage compression ultra-low temperature heating is the first research and development of SONGZ’s technical team among international counterparts. This technology is currently the best solution for low-temperature heating in severe cold areas of the industry.

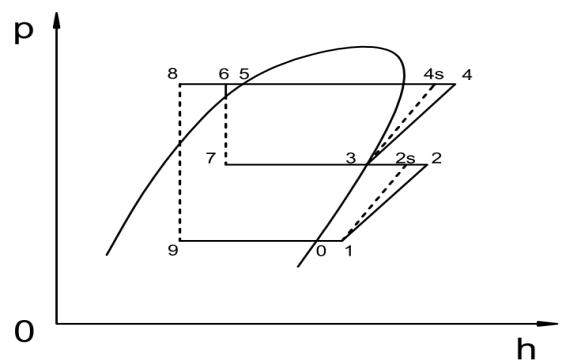

two-stage compression cycle

In the two-stage compression cycle, the refrigerant compression process is carried out in two stages, that is, the low-pressure refrigerant vapor from the evaporator first enters the low-pressure compressor, where it is compressed to an intermediate pressure, and then enters the high-pressure compressor, where it is compressed to condensation Pressure to achieve two-stage compression.

The two-stage compression pressure enthalpy diagram is as follows:

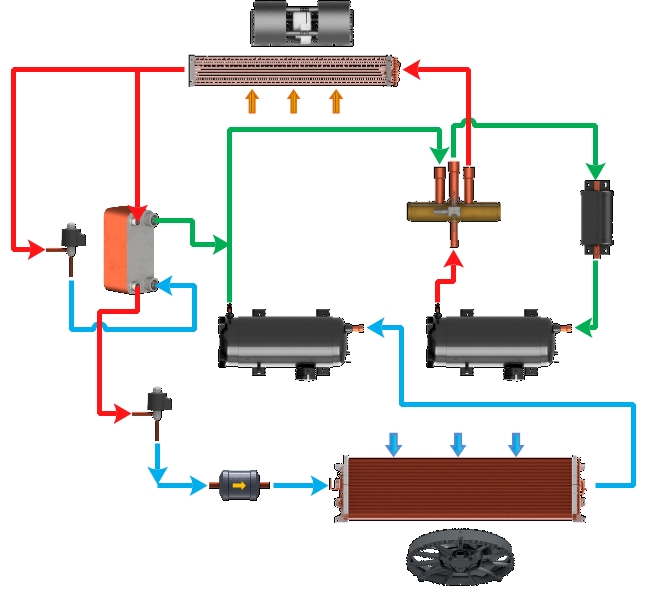

The system schematic diagram (heating part) is as follows:

Two-stage compression advantage

Reduce the compressor pressure ratio and reduce the problem of high power consumption caused by the high pressure ratio;

Increase the actual gas transmission volume and achieve high heating capacity;

Reduce the compressor discharge temperature and improve the reliability of system operation.

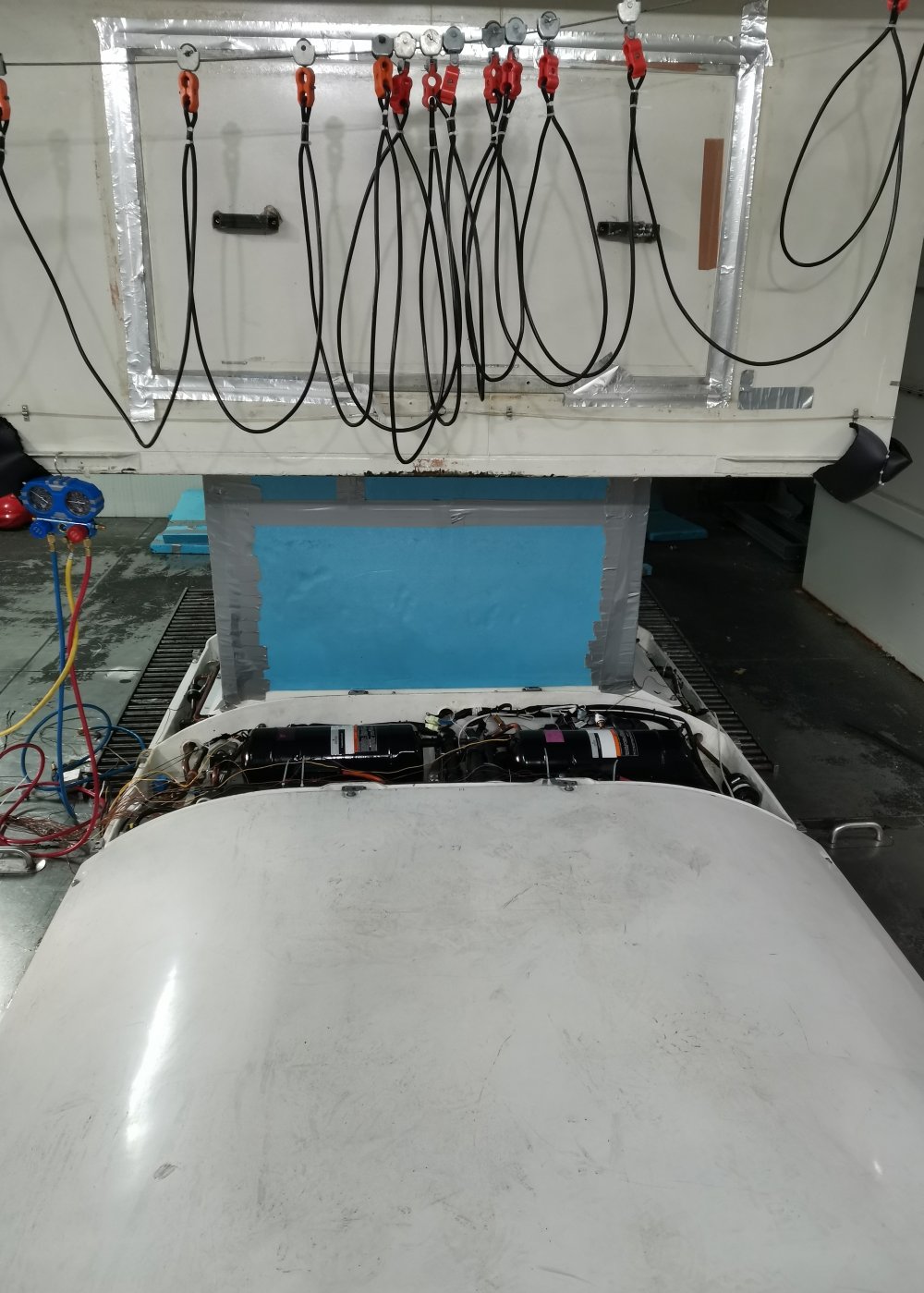

Whole vehicle wind channel matching

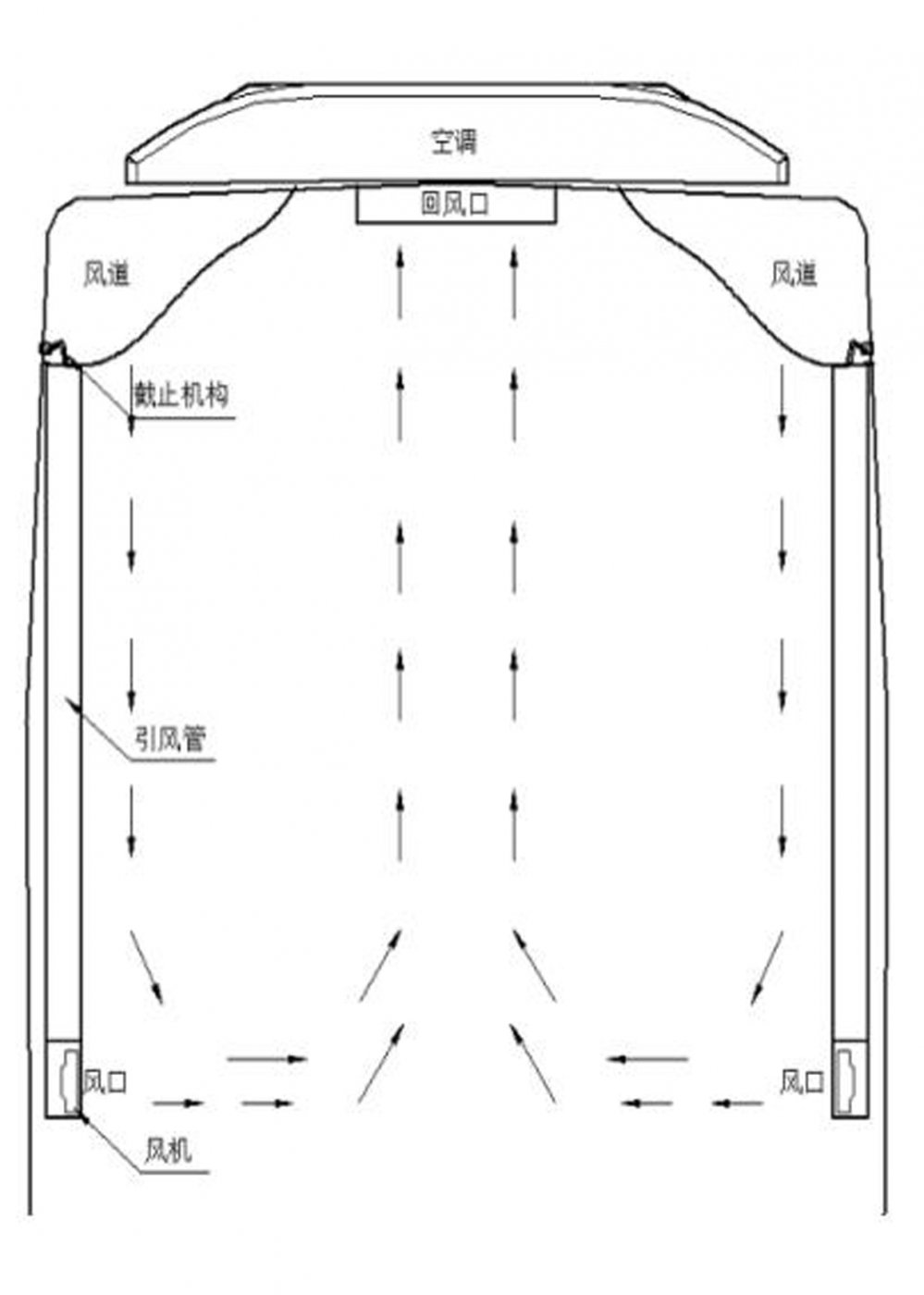

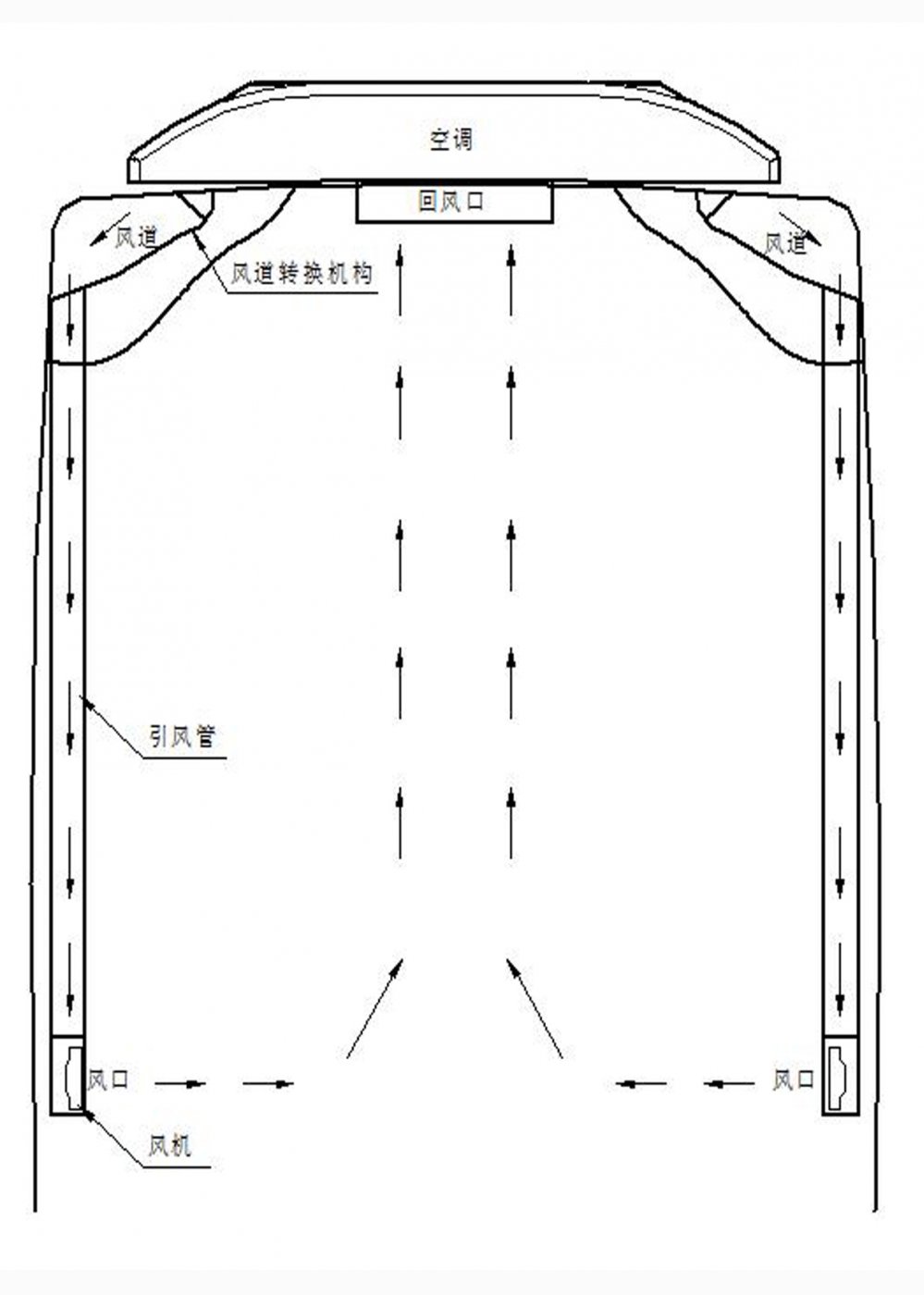

During the development and application of ultra-low temperature heat pumps, the SONGZ technical team found that the hot air from top to bottom does not meet the requirements of ergonomics and aerodynamics. Without changing the installation mode of the existing air-conditioning units and the main layout of the air ducts, the company applied for a patent for hot air ducts suitable for passenger car air-conditioning to achieve hot air downflow and improve passenger comfort.

Two different hot air down-citing patented technologies and application pictures

In 2020, the new airway agency combined with SONGZ ultra-low temperature heat pump units, and took the lead in applying it to public transport customers in a certain city. It just caught up with the historical low temperature of the city, and the feedback was good!

The two-stage compression ultra-low temperature heat pump 5.0 system adopts a high-efficiency DC inverter scroll compressor to realize stable and efficient operation of refrigeration, heat pump heating, and ultra-low temperature heat pump heating. Combining the air duct and thermal insulation optimization of the vehicle, the efficient heating of the vehicle at -30°C is just around the corner!

Post time: Apr-21-2021