In mid-2020, under the guidance of the leaders of the bus business department, the LMD series product upgrade project was officially launched, which took six months to achieve mass production and build the market power and product power of the SONGZ thermal management platform.

On February 2, 2021, the first batch of SMC molding units was successfully rolled off the Huaning Road plant, marking the successful completion of the LMD series product upgrade project.

Technology Highlights

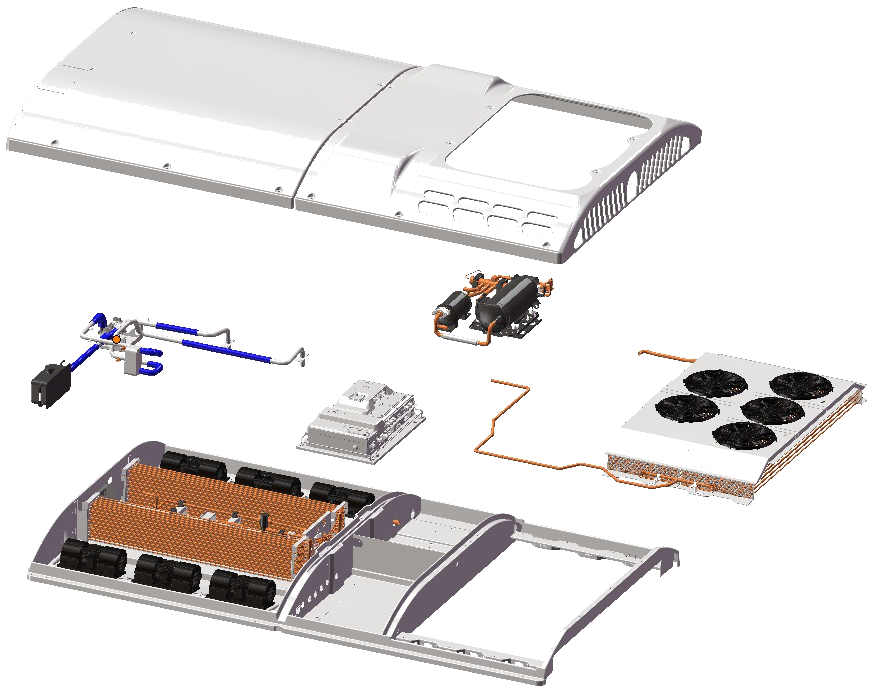

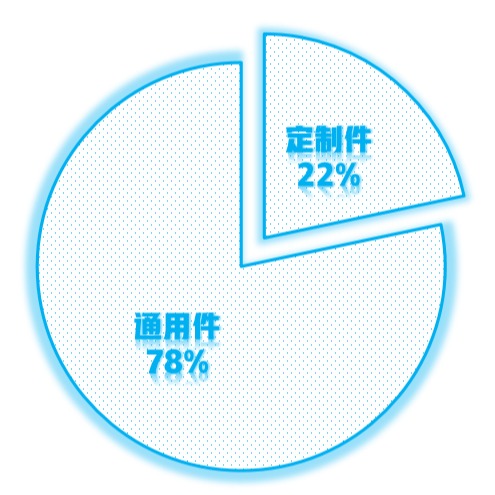

1. The intelligent modular platform design realizes the modular design and combination of components such as compressor unit, electrical control, evaporator, condenser, battery thermal management integration, etc. The product generalization rate is 78.3%, and the design is efficient and reliable.

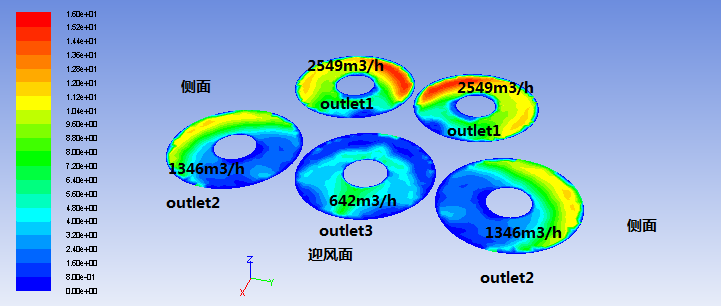

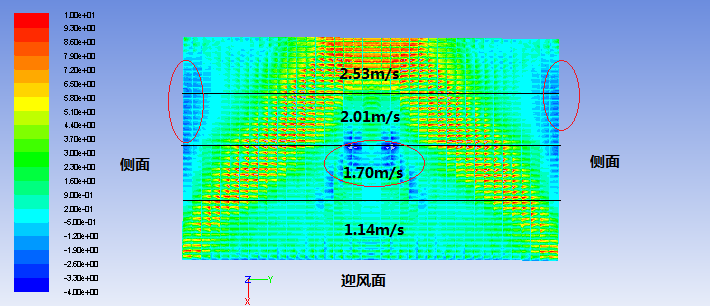

2. The condenser has no bottom shell and windward structure design, the product is light in weight and small in size; windward installation, fan simulation analysis layout, make full use of the driving wind of passenger cars, and improve the energy efficiency of product operation.

3. The product adopts the streamlined design of the SMC top cover with beautiful appearance. The compressor unit and the electric control part are integrated in the middle of the air conditioner, which is convenient and quick to maintain. The unique water tank access port design is convenient for filling.

4. The electric control part adopts aluminum alloy shell design, which can achieve IP54 and IP67 protection, fire and dustproof, high voltage and anti-reverse connection, and high electrical safety.

5. The EMC of the product meets the requirements of GB/T 18655 level 3, and the system adopts independent intellectual property rights insulation design, which is safe and reliable, and has passed EU standard certification.

6. Using adaptive frequency conversion technology, the system changes the power supply frequency according to different environmental conditions. At the same time, high-end products are equipped with electronic expansion valves, which are precisely controlled, energy-saving and consumption-reducing. The average seasonal power consumption is 2 to 4KW, and the driving experience is comfortable and pleasant.

7. The same external dimensions expand and widen the air duct by 1480 mm, and the platform is compatible with the static pressure air duct and economical air duct with wider air outlet requirements for passenger cars.

8. Unique integrated battery thermal management waterway system design, when the client has no auxiliary filling equipment, the system can be automatically drained.

Function Upgrade

In addition to satisfying basic functions such as refrigeration, heat pump heating, and ventilation, the product can also upgrade the following functions according to customer and environmental requirements:

1. Ultra-low temperature heat pump heating function 3.0, achieving high energy efficiency at -15°C ambient temperature to meet the heat load of the vehicle, and continuous heat pump operation at -25°C ambient temperature. When heavy snow is covered, manual defrosting and automatic snow can be realized, saving energy and reducing consumption.

2. Ultra-low temperature heat pump heating function 4.0, using independent innovation and special frequency conversion air supplement control technology to achieve high energy efficiency of air conditioners at -20°C to meet the heat load of the vehicle, and continuous heat pump operation at -30°C ambient temperature.

3. Ultra-low temperature heat pump heating function 5.0, innovatively developed two-stage compression system, which can achieve -25℃ ambient temperature and high energy efficiency to meet the heat load of the whole vehicle, and continuous heat pump operation at -35℃ ambient temperature.

4. The original integrated battery cooling design, the air conditioner provides heat pump heating for the carriage, and at the same time provides cooling function for the power battery pack. Regardless of whether the air conditioning system is in the cooling or heating process, it can output a battery cooling capacity of 3-10kw, completely replacing independent battery thermal management.

5. Air purification function, including the four major functions of electrostatic dust collection, ultraviolet light, strong ion generator, and photocatalyst filtration, to achieve sterilization, deodorization and efficient dust removal, and effectively block the virus transmission path.

6. The “cloud control” function realizes remote control and program upgrades, and improves product service and monitoring capabilities through big data applications.

Think what the customer thinks, anxious what the customer wants,

Constantly challenge ourselves and forge ahead on the road of product strength,

Leading the development of bus thermal management industry!

Post time: Apr-23-2021