FAQ

Frequently Asked Questions

Yes, we have products available also of truck air conditioner and electric parking cooler, please contact with sales@shsongz.com for more details.

We started the R&D before 2009, and in 2010 the first year we supplied 3250 units to the market. After then, the sales quantity is growing year by year and hitting the top of 28737 in 2019.

SMC (Sheet Mounding Compound) composite material is molded by high temperature in once molding, with high mechanical strength, light weight material, corrosion resistance, long service life, high insulation strength, arc resistance, flame retardant, good sealing performance, and flexible product design, easy to scale production, And it has the advantages of safety and beauty, with all-weather protection function, which can meet the needs of various harsh environments and places in outdoor engineering projects.

SONGZ adopts the material of SMC in the cover of the bus air conditioner in the SZR and SZQ series, to take the place of the fiber glass cover.

The Comparison between SMC & Fiber glass Cover

|

Compared Items |

Fiber Glass |

SMC Molding |

| Process type | The process of making composite materials mainly by manual operation under high temperature and pressure. The process is simple, the operation is convenient, no professional equipment is needed, but the quality of the parts is difficult to guarantee | Compression molding is the operation of putting SMC sheet-like molding compound into the mold cavity at a certain molding temperature, and then closing the mold to press and shape and solidify. Compression molding can be used for thermosetting plastics and thermoplastics. |

| Product surface smoothness | Smooth on one side, and the quality depends on worker operation level | Smooth on both sides, good quality |

| Product deformation | The product has a large amount of deformation and is not easy to control. It is greatly affected by temperature and manual operation | The deformation of the product is small, and has little relationship with the temperature and the level of workers |

| Bubble | Due to the molding process, the thickness is determined by the number of laminated layers, the layers are not easy to penetrate, the bubbles are not easy to remove, and the bubbles are easy to produce | The thickness is determined by the feeding amount and the mold. Due to the high temperature and high pressure molding, it is not easy to produce bubbles |

| Crack | 1. Due to the large amount of product deformation, it is not easy to control, and it is not easy to install during installation.2. Low temperature curing slow production, resulting in micro-cracks on the product surface

3. Due to the small stiffness of the product, the elasticity is greater than that of the molding, and the surface paint is prone to the fine lines of the product |

The product is stable, unless the local strength is not enough, stress concentration leads to cracking |

| Output | The initial investment is low, the output is low, and it is not suitable for batches. The output is greatly affected by the number of employees and the number of molds (3-4 pieces/mold/8 hours) | Large initial investment, suitable for mass production (180-200 pieces/mold/24 hours) |

LFT is also known as long-fiber-reinforced thermoplastic or customarily called long-fiber-reinforced thermoplastic composite material, which is mainly composed of PP and fiber plus additives. The use of different additives can change and affect the mechanical and special application characteristics of the product. The length of the fiber is generally greater than 2mm. The current processing technology can already maintain the length of the fiber in the LFT above 5mm. Using different fibers for different resins can achieve better results. Depending on the end use, the finished product can be long or strip-shaped, a certain width of plate, or even a bar, directly used for replacement of thermoset products.

The longer fiber length significantly improves the mechanical properties of the product.

High specific stiffness and specific strength, good impact resistance, especially suitable for the application of automotive parts.

The creep resistance is improved. The dimensional stability is good. And the forming precision of the parts is high.

Excellent fatigue resistance.

It has better stability in high temperature and humid environment.

During the molding process, the fibers can move relatively in the forming mold, and the fiber damage is small.

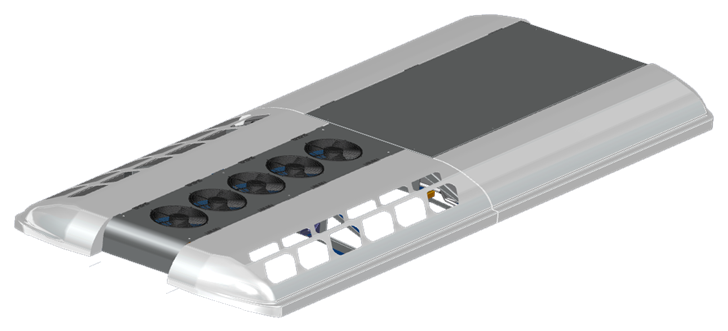

The LFT material has been adopted into the bus air conditioning of SZR series, SZQ series, and the narrow body version of SZG series.

LFT Bottom Shell for SZG (Narrow Body)